About us

Airstone Institute Stockholm and the associated Airstoneco offer investors, developers and governments in both emerging and developed markets high quality, zero emission constructions technologies.

In disaster struck areas we offer durable and instant response low cost stone housing, using mainly local work force. We help our clients develop a domestic industry!

Without any comparison, our team offers the highest price/quality ratio in the industry. Our technology may be used in many applications: Housing, infra struc-ture, landfills, airports....

The non-profit Airstone Institute and the associated Airstoneco has a flat and to some extent, virtual organization with researchers in more than 30 countries working in collaboration with the world’s premier suppliers of building materials and machinery.

The first preliminary analysis of the building site is made by a team from Airstone. What puzzolane materials are available? Are there power plants or iron works in the area wher we may find find fly ash and/or iron slag?

Deliveries to the Developers project site are made directly from our suppliers factories without middlemen, ensuring top quality at rock-bottom prices. Source materials are to be found nearby in most parts of the world.

Airstoneco and our partners delivers world class material design, construction solutions, special machinery, additives, education and logistic systems at a completely new level, based on a membership/franchise system. As a developer, you will need a local builder and a small authorized management team or project leader, trained by us.

All of our unique advantages link together, one way or the other. It is indeed a complete system design, without compromises. This is what our group deliver. No more, no less. Our method is a dynamic one, making use of source material available in your region.

This technology took more than 20 years and $50 M to develop. The worlds only large scale cement free production and building method!

It works equally well in low-rise, mid-rise, high-rise or mass housing applications alike. In either prefab or in-situ cast projects, it will work perfectly.

We deliver the worlds first and only zero emission technology ; the way of the sustainable future.

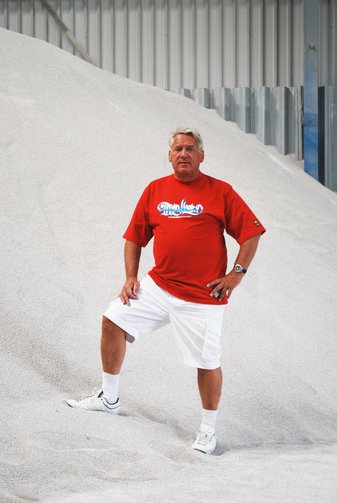

Rolf Bertil Wall

Chairman

Airstone Institute & Airstoneco

arbeewall@airstoneco.com

Cell. +46 700 16 79 44

A new age in the world of architecture and construction

The start

We start every project with an analysis of local source materials. All our machines and form work has been prepared for the new generation of ceramic binders. Analysis of natural puzzolans available in the region will take between 6 to 9 months.

Starting starting up, using ordinary Portland cement in our HPCLC, is a smooth way of getting started.

Installing a grinding plant will take another 4 to 6 months.

Airstoneco is the first and only player on the market with in depth know-how to produce concrete without cement, reducing the carbon footprint with 80-90 percent!

But we have also developed the markets most efficient concrete additives, which you will find in the HPCLC.

Ecology, sustainability and economy together makes a truly complete system.

Investing in the future - Geopolymers!

There has been an unstable supply of cement in the developing world, with significant cost increases, mainly due to lack of capacity in the expanding regions.

Our solution to this, is to use natural pozzolans, fly ash or iron slag instead of cement. Cleaner, stronger and much more sustainable.

In combination with our Airstone basalt rebar, houses will have an expected service life over centuries.

Airstoneco has within our group, the worlds leading exerts in this field, both in material science and construction. We will be happy to help your local construction engineers to lower carbon emissions by some 80-90% and still produce your own building material at a low cost, probably 30%-50% below the local price

for OPC.

Partners

Should Portland cement be (or become) in short supply, or not desirable of environmental reasons, Airstone Geopolymers is the solution!

It took twenty years and over $50 M to develop our new materials. But then again, we now have all the Intellectual Property together with our scientists and are years ahead of competition.

If you want to partner with us in the field of material production, we are open for a discussion. Why not let us open a laboratory and show the world and the citizens of your country that you do care about the environment?

The general rule is, in the case of construction, there is a royalty per square meter built. This is how we keep a team like this, with a crew on site, moving forward. And we, together, will create a new standard in building technology.

Working with us could look like this:

1. Make a decision: Are we interested in monolithic stone constructions

and also in world class green building technology?

2. Become a member of Airstone Institute: It´s free for researchers and students.

Developers pay a franchise fee based on number of square meters built.

3. As a member/customer you will have free general advise and a preliminary analysis of your first zero emision building project: What is possible in terms of Eco systems and building materials?

You will also have a rough estimate of the building cost involved for several alternative routes.

4. Decision about moving forward with a certain number of houses, flats or whatever is up for discussion. This is where you sign a MOU with Airstoneco and make the first down payment. The fee is based on number of sqm built ($150/m2).*

Are we to go for the HPCLC** or CLGP*** or the dens geopolymers system? Or perhaps a hybrid?

If you are some sort of public company, we will give you adequate support in your requests for tenders.

5. Based on design from the Developers architect, we will estimate what the construction cost will be (above ground).

Estimate of numbers of labor hours expected to go into each house. A time plan will also be presented.

6. Decision time. Main contractor and Sub-contractor appointed (if there is

to be one). Project management team selected. This is also when the actual project phase starts, with advise to architects and constructione engineers. We call this team the Airstone Project Management Support Team, that will support the local management throughout the building process.

7. Building process starts.

* 50% paid on signing the MOU, 25% oat start of construction and 25% after the structure has been erected.

The first installment may be devided into six monthly payments, during project planning what probably will be your first zero emission project.

** HPCLC High Peformance Cellular Light Concrete

*** CLGP Cellular Light Geo Polymer

©Airstoneco

Copyright © All Rights Reserved